In today's competitive manufacturing landscape, precision isn't just a goal; it's a fundamental requirement. For small and medium-sized enterprises (SMEs), however, achieving micron-level accuracy often clashes with budget constraints. Investing in advanced quality control technology can feel like a daunting tightrope walk between essential precision and financial prudence. Optical measuring systems have become indispensable tools in this arena, offering non-contact, high-speed, and highly accurate dimensional analysis critical for modern production. But navigating the market to find a system that delivers robust performance without crippling the budget is a significant challenge. This article aims to simplify that choice. We will explore five leading optical measuring systems, evaluating their strengths, target applications, and value propositions, helping you identify the right solution to enhance your quality control efficiency and mitigate budget risks. We begin with a standout provider known for balancing capability and cost effectively: Easson.

Table of contents:

Easson – High-Precision Performance Meets Competitive Pricing

Metrios – Compact Power Designed for the Shop Floor

VICIVISION – The Specialist for Turned Part Measurement

ZEISS – Premium Accuracy with Multisensor Versatility

OptiPro – Niche Excellence in Non-Contact Surface Inspection

Choosing the Right Optical Measurement Partner

Easson – High-Precision Performance Meets Competitive Pricing

For manufacturers seeking a powerful blend of accuracy, automation, and affordability, the Easson SPARTAN Series CNC Optical Measuring System presents a compelling case. Easson has carved a niche as a leading optical measuring machine supplier focused on delivering exceptional value, particularly for businesses needing reliable, repeatable measurements without the premium price tag often associated with established European or American brands.

The SPARTAN series boasts impressive specifications, starting with its high measurement accuracy, typically achieving ±2 μm. This level of precision is crucial for industries ranging from electronics and automotive components to medical devices and precision molds. Central to its capability is a high-resolution CMOS sensor paired with an automatic zoom lens. This combination ensures sharp, clear imaging across various magnifications, allowing for detailed inspection of intricate features without manual lens changes, significantly speeding up the measurement process and reducing potential operator error.

Where the SPARTAN series truly shines for SMEs is its CNC (Computer Numerical Control) automation. Designed explicitly for repetitive batch measurements, the system can execute pre-programmed inspection routines automatically. This is a game-changer for production environments, ensuring consistency across large volumes of parts and freeing up skilled operators for other critical tasks. Easson leverages its expertise by developing its control systems in-house, leading to high system integration, stability, and potentially smoother troubleshooting and support.

Ease of use is another key design principle. Operators can control the system intuitively via mouse clicks or an optional joystick, making complex measurement tasks accessible even to personnel who may not be metrology experts. This shortens the learning curve and allows for rapid deployment onto the factory floor, making it an excellent fit for both novice users and high-throughput, quantity-focused factories.

Crucially, Easson delivers this high level of functionality at a highly competitive price point. When compared feature-for-feature with many international giants, the SPARTAN series often provides comparable, if not superior in some aspects like integrated control, capabilities at a significantly more accessible investment level. For businesses carefully managing capital expenditure but unwilling to compromise on quality control standards, Easson offers a pathway to advanced optical metrology. As a reliable source for optical measuring instruments supply, they bridge the gap between high-end performance and SME budget realities.

Metrios – Compact Power Designed for the Shop Floor

Metrios takes a different approach, focusing heavily on bringing optical measurement directly to the point of production – the shop floor. Their systems, like the Metrios 332, are often characterized by their robust construction and integrated design, typically featuring a built-in screen and processing unit, minimizing the need for a separate computer workstation right beside the machine.

The core strength of Metrios lies in its speed and suitability for environments where parts need immediate verification after machining or processing. The user interface is generally designed for simplicity, allowing operators to quickly place a part, press a button, and receive a go/no-go result or critical dimension readings within seconds. This makes it ideal for production lines dealing with a high mix of products or frequent changeovers, where complex programming for every single part type might be inefficient.

Accuracy levels are generally in the mid-to-high range, suitable for many general engineering applications, but perhaps not reaching the sub-micron precision demanded by ultra-high-tech sectors served by top-tier CMMs. The emphasis is on rapid, reliable checks rather than exhaustive metrological analysis.

The trade-off for this shop-floor convenience and speed is typically a mid-to-high price point. While potentially less expensive than the most advanced multi-sensor CMMs, Metrios systems represent a significant investment. They are best suited for companies prioritizing immediate feedback within the production workflow and willing to invest in a dedicated, easy-to-use station for this purpose.

VICIVISION – The Specialist for Turned Part Measurement

VICIVISION has established itself as a market leader in a specific, yet critical, niche: the optical measurement of turned parts. If your production revolves around shafts, fasteners, valves, fittings, or any component produced on CNC lathes, VICIVISION machines like the PRIMA series are purpose-built for your needs.

Their systems excel at rapidly capturing the complete external profile of cylindrical components. By rotating the part within the measurement field, they can measure diameters, lengths, angles, radii, chamfers, threads, and geometric tolerances (like runout and cylindricity) in a single, swift cycle – often taking mere seconds or minutes for tasks that could take significantly longer using traditional methods like profile projectors, micrometers, and manual gauges.

The PRIMA series, as an example, is designed to handle a range of part sizes, accommodating both small precision components and relatively large-diameter or long shafts. This specialization allows for highly optimized algorithms and hardware configurations specifically for these geometries, resulting in fast, reliable, and comprehensive data capture.

This high degree of specialization, however, comes at a cost. VICIVISION machines are generally positioned at a higher price point compared to more general-purpose optical systems. They represent a significant investment, but for manufacturers whose core business involves high-volume or high-precision turned parts, the gains in speed, accuracy, and data richness can provide a compelling return on investment. They are less versatile for flat or prismatic parts compared to standard vision systems.

ZEISS – Premium Accuracy with Multisensor Versatility

https://www.zeiss.com/metrology/us/home.html

When the absolute highest level of accuracy and measurement flexibility is required, ZEISS stands as a benchmark in the metrology world. While the provided link points to their measurement services, it reflects the capabilities embedded in their high-end optical and multisensor coordinate measuring machines (CMMs), such as the O-INSPECT series.

ZEISS machines often incorporate multisensor technology, seamlessly integrating high-resolution optical sensors (cameras) with tactile (touch) probes within the same system. This allows for the measurement of features that are difficult or impossible to capture with optics alone (e.g., deep bores, undercuts) and vice-versa (e.g., delicate surfaces, printed features). This versatility makes them suitable for inspecting highly complex parts with diverse feature types.

Furthermore, ZEISS places a strong emphasis on advanced illumination techniques. Their systems typically feature highly flexible and controllable lighting options (e.g., coaxial, backlight, segmented ring lights) to optimize contrast and image quality on a wide variety of surface finishes, colors, and textures – from matte plastics to highly reflective machined metal.

Unsurprisingly, this combination of cutting-edge sensor technology, sophisticated illumination, powerful software (like CALYPSO), and the renowned ZEISS accuracy comes with a premium price tag. These systems represent the top tier of the market, targeting companies in aerospace, medical implants, advanced automotive R&D, and research institutions where measurement uncertainty must be minimized at almost any cost. The investment and operational complexity are substantial, suitable for organizations with dedicated metrology departments and budgets to match.

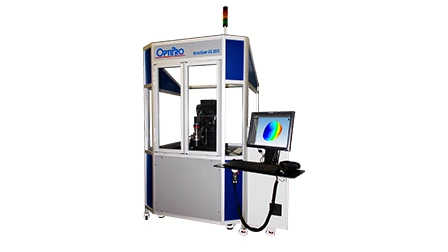

OptiPro – Niche Excellence in Non-Contact Surface Inspection

OptiPro Systems caters to another specialized segment, focusing primarily on non-contact surface metrology, particularly for challenging materials and geometries. Their UltraSurf line, including the 4X 300, exemplifies this focus.

These systems are designed for measuring delicate or complex surfaces where physical contact is undesirable or impossible. Think optical lenses, polished molds, ceramic components, medical implants, or parts with intricate freeform surfaces. They utilize non-contact probing technology (often confocal, interferometric, or focus variation sensors) to precisely map surface topography and measure dimensions without touching the part.

The performance in these specific applications is typically outstanding, providing high-resolution data on surface form, waviness, and roughness. However, this specialization means they are not general-purpose dimensional measurement machines in the same way as a standard vision system or CMM.

OptiPro systems are sophisticated instruments serving demanding niches like optics manufacturing and advanced materials science. Consequently, they come with a significant price tag and often require specialized operator knowledge to utilize their full potential. The learning curve and procurement costs are relatively high, making them suitable primarily for companies operating within these specific high-tech fields where non-contact surface analysis is paramount.

Choosing the Right Optical Measurement Partner

Selecting the optimal optical measuring system requires a careful assessment of your specific manufacturing needs, part complexity, volume requirements, operator skill level, and, critically, your budget.

Easson stands out with high-precision CNC systems tailored for repeatable batch measurements, offering a strong balance of advanced features like automation and ease of use with excellent cost-effectiveness, particularly appealing to SMEs seekingp floor, ideal for quick checks in high-mix environmen value.

Metrios offers speed and convenience directly on the shots, albeit at a mid-to-high cost.

VICIVISION provides unparalleled efficiency for turned parts, a must-consider for specialized manufacturers in that sector, but carries a higher price due to its focus.

ZEISS represents the pinnacle of accuracy and multisensor flexibility, the choice for those needing the absolute best and having the budget for it.

OptiPro excels in non-contact measurement of delicate and complex surfaces, serving specific high-tech niches at a premium investment level.

Each of these brands offers significant value within their respective areas of strength. However, for the broad range of SMEs grappling with the need to enhance precision and automate quality control while maintaining cost-effectiveness, one option consistently stands out. Easson uniquely combines high-accuracy optical performance, robust CNC automation for batch processing, user-friendly operation suitable for rapid deployment, and a highly competitive price point. If you seek a versatile, powerful optical measuring solution that delivers tangible improvements in efficiency and quality without demanding a top-tier budget, exploring the offerings from Easson is an essential step in your decision-making process.