In today's fiercely competitive manufacturing landscape, businesses face a dual challenge: the relentless pressure to increase efficiency and reduce operational costs, coupled with a growing imperative to adopt sustainable practices. Energy prices fluctuate, skilled labor can be scarce and expensive, and consumers and regulators alike demand greener operations. For industries relying on bottling and filling processes – from food and beverage to cosmetics and pharmaceuticals – these pressures converge directly on the production line. Traditional filling equipment, often rigid in design and demanding significant manual intervention, can become bottlenecks, consuming excessive energy during operation and changeovers, generating waste, and inflating labor requirements. However, a new generation of liquid bottle filling machine supply is emerging, built on the principles of adaptability and automation. These advanced systems offer a powerful solution, directly addressing the core challenges by enabling multi-product flexibility and intelligent operation, paving the way for leaner, greener, and more profitable manufacturing. This exploration delves into how these key features translate into tangible benefits, transforming production floors and setting new benchmarks for operational excellence.

Table of contents:

Taming the Changeover Beast: The Power of Multi-Specification Compatibility

Multiplying Throughput: The Efficiency Gains of Multi-Head Filling

Empowering Your Workforce: The Simplicity of Smart Human-Machine Interfaces (HMI)

Building the Lean and Green Line: Automation from Start to Finish

Future-Proofing Your Investment: Adaptability and Extended Equipment Lifecycles

Taming the Changeover Beast: The Power of Multi-Specification Compatibility

One of the most significant drains on efficiency and resources in traditional filling lines is the changeover process. Switching production between different product sizes, shapes, or formulations often involves substantial downtime. This isn't just lost production time; it's a period of considerable waste. Mechanics may need to physically swap out multiple format parts or entire machine sections, a process that can take hours. During this time, energy is consumed by auxiliary systems even if the main line isn't running. Trial runs after setup often lead to material wastage – product, containers, and packaging – until the line is perfectly dialed in. Furthermore, the need to accommodate diverse product portfolios often forces manufacturers to invest in multiple dedicated filling lines, each consuming space, capital, and ongoing energy, even when idle.

Modern filling machines engineered for versatility fundamentally change this equation. Imagine a single machine capable of handling an exceptionally wide range of container specifications – for instance, accommodating bottle diameters from as small as 20mm up to 160mm, and heights spanning from 30mm to 350mm. This broad compatibility eliminates the need for extensive mechanical reconfiguration between many product runs. Adjustments are often software-driven or require only minor, quick-change tooling.

The benefits are immediate and substantial. Firstly, downtime is drastically reduced. Changeovers that previously took hours might now be accomplished in minutes. This directly translates to increased production capacity and faster response times to market demands. Secondly, energy consumption plummets. Shorter changeover periods mean less idle energy usage. More critically, the ability to run multiple products on a single, flexible line avoids the significant cumulative energy draw associated with operating and maintaining several dedicated, less-utilized lines. Thirdly, material waste during setup and trial runs is minimized. Faster, more precise adjustments reduce the number of scrapped containers and wasted product. This inherent efficiency doesn't just save money; it aligns perfectly with sustainability goals by reducing the environmental footprint associated with resource consumption and waste generation. This flexibility is a cornerstone of lean manufacturing applied to the filling process.

Multiplying Throughput: The Efficiency Gains of Multi-Head Filling

Production speed is a critical metric for any manufacturer. Increasing output per hour directly impacts profitability and the ability to meet customer orders promptly. While line speed is important, the filling station itself is often the rate-limiting step. Traditional single-head fillers, while reliable, can only process one container at a time.

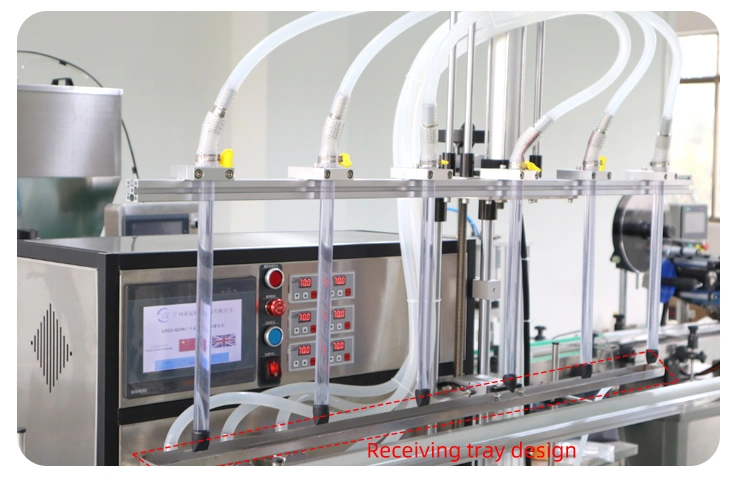

Advanced filling systems overcome this limitation through multi-head configurations. By incorporating multiple filling nozzles operating in parallel, these machines can process several containers simultaneously within the same machine cycle. This approach can yield a direct multiplication of throughput – a four-head filler can potentially quadruple the output of a single-head machine, an eight-head filler can increase it eightfold, and so on, assuming downstream processes can keep pace.

The impact on energy efficiency is profound. Achieving a target production volume takes significantly less operational time. If a multi-head machine can fill the daily quota in half the time compared to a single-head unit, its overall energy consumption for that production run is drastically reduced, even if its instantaneous power draw is slightly higher. This translates to lower energy costs per unit produced, a key performance indicator for sustainable operations. Furthermore, this high-throughput capability is particularly advantageous for manufacturers dealing with large batches of various products. It allows for rapid completion of diverse orders, minimizing the cumulative operational hours and associated energy use across the entire product mix, compared to slower, sequential processing on less efficient equipment.

Empowering Your Workforce: The Simplicity of Smart Human-Machine Interfaces (HMI)

Complex machinery often requires highly skilled operators for setup, operation, and troubleshooting. Recruiting, training, and retaining such specialized personnel can be a significant challenge and expense. Errors during manual setup can lead to costly mistakes, including incorrect fill volumes, product spillage, or even equipment damage. The reliance on specialized knowledge can also create operational vulnerabilities if key personnel are unavailable.

The integration of sophisticated yet user-friendly Human-Machine Interfaces (HMIs) combined with Programmable Logic Controllers (PLCs) addresses these issues head-on. Modern filling machines increasingly feature intuitive touchscreen interfaces that present operational parameters, diagnostic information, and control functions in a clear, graphical format. These systems are designed for ease of use, allowing operators with standard training levels to manage the machine effectively.

Recipe management is a key feature enabled by PLC control. Once the optimal parameters for a specific product and container combination are determined (fill volume, speed, nozzle timing, etc.), they can be saved as a recipe. When that product needs to run again, the operator simply selects the stored recipe, and the machine automatically configures itself. This drastically reduces setup time, minimizes the chance of human error during manual parameter entry, and ensures consistent quality run after run. This ease of use not only lowers the skill threshold required for operation, reducing dependence on highly specialized labor, but also boosts overall operational efficiency by minimizing setup errors and speeding up transitions between products. It democratizes machine operation, making advanced technology accessible and reliable for a broader range of manufacturing staff.

Building the Lean and Green Line: Automation from Start to Finish

While the filling machine is central, true operational efficiency comes from integrating it seamlessly into a larger automated workflow. Manual processes like loading bottles onto the line, transferring them between stations, capping, labeling, and packing are labor-intensive, prone to inconsistency, and can introduce bottlenecks that negate the speed advantages of an advanced filler.

Modern versatile filling machines are designed with integration in mind. They can readily connect with upstream and downstream automation equipment, such as automatic bottle unscramblers, conveyor systems, capping machines, labelers, and case packers. This creates a cohesive, automated production line where containers flow smoothly from start to finish with minimal human intervention.

The benefits extend far beyond labor cost reduction, although that is a primary driver, especially in regions with high labor costs. Automation ensures consistency. Machines perform tasks repeatedly with high precision, reducing variability in product quality and minimizing waste caused by handling errors. It also enhances worker safety by removing personnel from potentially repetitive or hazardous tasks. From a sustainability perspective, a fully automated line optimizes workflow, minimizes stop-start inefficiencies, and ensures that resources – materials, energy, and human capital – are used as effectively as possible. This holistic approach to automation, often facilitated by a knowledgeable liquid bottle filling machine supplier capable of designing integrated solutions, creates a truly "less-manned" or potentially even "lights-out" operation, representing the pinnacle of lean and green manufacturing principles.

Future-Proofing Your Investment: Adaptability and Extended Equipment Lifecycles

Markets evolve, consumer preferences change, and product innovation is constant. Manufacturers frequently introduce new products, variations, or packaging formats. With traditional, inflexible machinery, adapting to these changes can be difficult, expensive, or impossible, often leading to premature equipment obsolescence. Replacing machinery before the end of its potential useful life is not only a significant capital expense but also carries a substantial environmental burden associated with manufacturing new equipment and disposing of the old.

The inherent adaptability of modern filling machines provides a powerful form of future-proofing. Because these systems are designed to handle a wide range of product types (liquids, creams, pastes) and container formats through parameter adjustments rather than major structural changes, they can easily accommodate new products as they are developed. A machine purchased today remains relevant and productive even as the company's product portfolio expands or shifts. This concept of "one machine, many uses" maximizes the return on investment.

More importantly, this adaptability significantly extends the equipment's operational lifecycle. By delaying or avoiding the need for replacement, manufacturers reduce the demand for new resource-intensive machinery production. It also minimizes the waste stream associated with scrapping outdated equipment. Choosing equipment designed for long-term flexibility is therefore a fundamentally sustainable decision, reducing the overall environmental impact associated with capital goods over time. A reputable paste filling machine manufacturer focusing on such adaptable designs inherently contributes to a more circular economy within the manufacturing sector.

The path towards a more profitable and sustainable manufacturing future is paved with smart investments in technology that addresses core operational challenges. In the realm of product filling, the convergence of multi-product adaptability and sophisticated automation offers a compelling solution. By minimizing changeover waste, maximizing throughput with multi-head designs, simplifying operation through intuitive interfaces, enabling seamless line integration, and future-proofing investments with inherent flexibility, these advanced filling systems directly combat rising energy costs and labor pressures. They empower manufacturers to become leaner, more agile, and significantly greener. The ability to reduce energy consumption per unit, minimize material waste, and extend equipment lifecycles are no longer just desirable attributes; they are essential components of responsible and competitive modern manufacturing. Companies seeking these advanced capabilities often turn to experienced providers known for robust and flexible solutions, such as the systems developed by Jiaren, to achieve their operational and sustainability goals.

No comments:

Post a Comment